OUR SUPPLIER CANDIANI

Years of business expertise

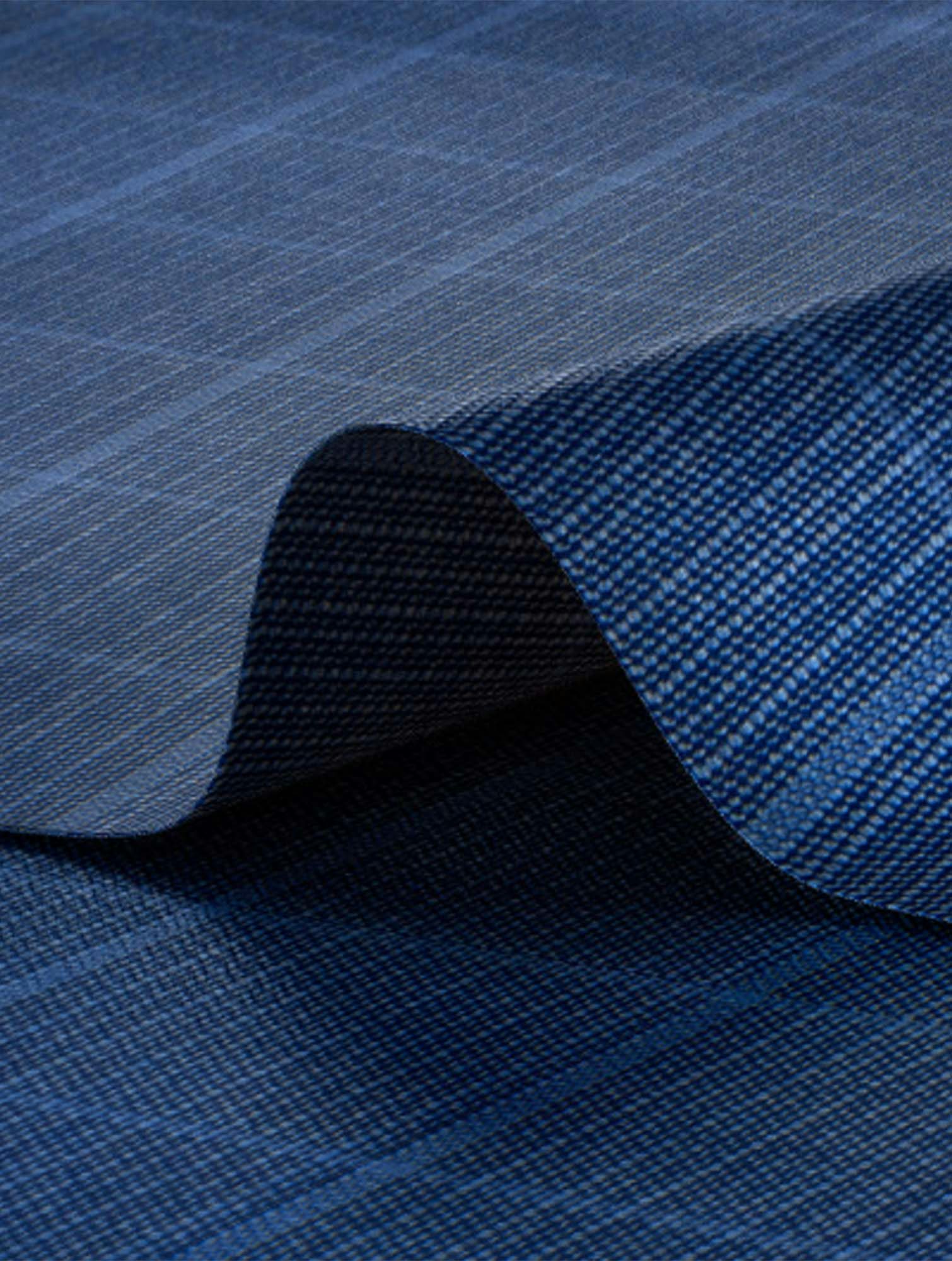

Candiani, an Italian family enterprise based near Milan, has been specialising in the production of denim for more than 80 years. Producing sustainable jeans is no easy task. But it is an absolute requirement for this denim supplier. Environmental protection is a top priority at Candiani. Candiani uses around 15 per cent less water and energy. The Italian supplier is one of our trusted partners. Our cooperation is not only defined by our shared focus on sustainability, but in particular by the following key aspects.

By viewing the video, you agree to a data transmission to Vimeo.The data processing by Vimeo is governed by their privacy policy.More Information

Sustainable jeans production

It’s no secret: Jeans are one of the most challenging products in terms of sustainability. Up to 8000 litres of water are used for a conventional pair of denim jeans. Then there are the numerous chemicals that find their way back into the ecosystem. Which makes the achievement of our Italian partner Candiani all the more remarkable. The denim weaving mill has made a name for itself in the market since 1938 and is a successful player in the global economy. The focus on sustainability has its reasons. When the location of our partner’s mill on the Ticino River was declared a nature reserve, strict environmental regulations were the result. The initial challenge became a specification with future potential. The new regulations demanded innovative technology and an improvement of the standard production process. They stipulated that the discharged water had to comply with much stricter threshold values and that the dyeing agents had to be significantly improved. The events that took place here around 50 years ago paved the way for a sustainable production method.

Environmentally clean jeans

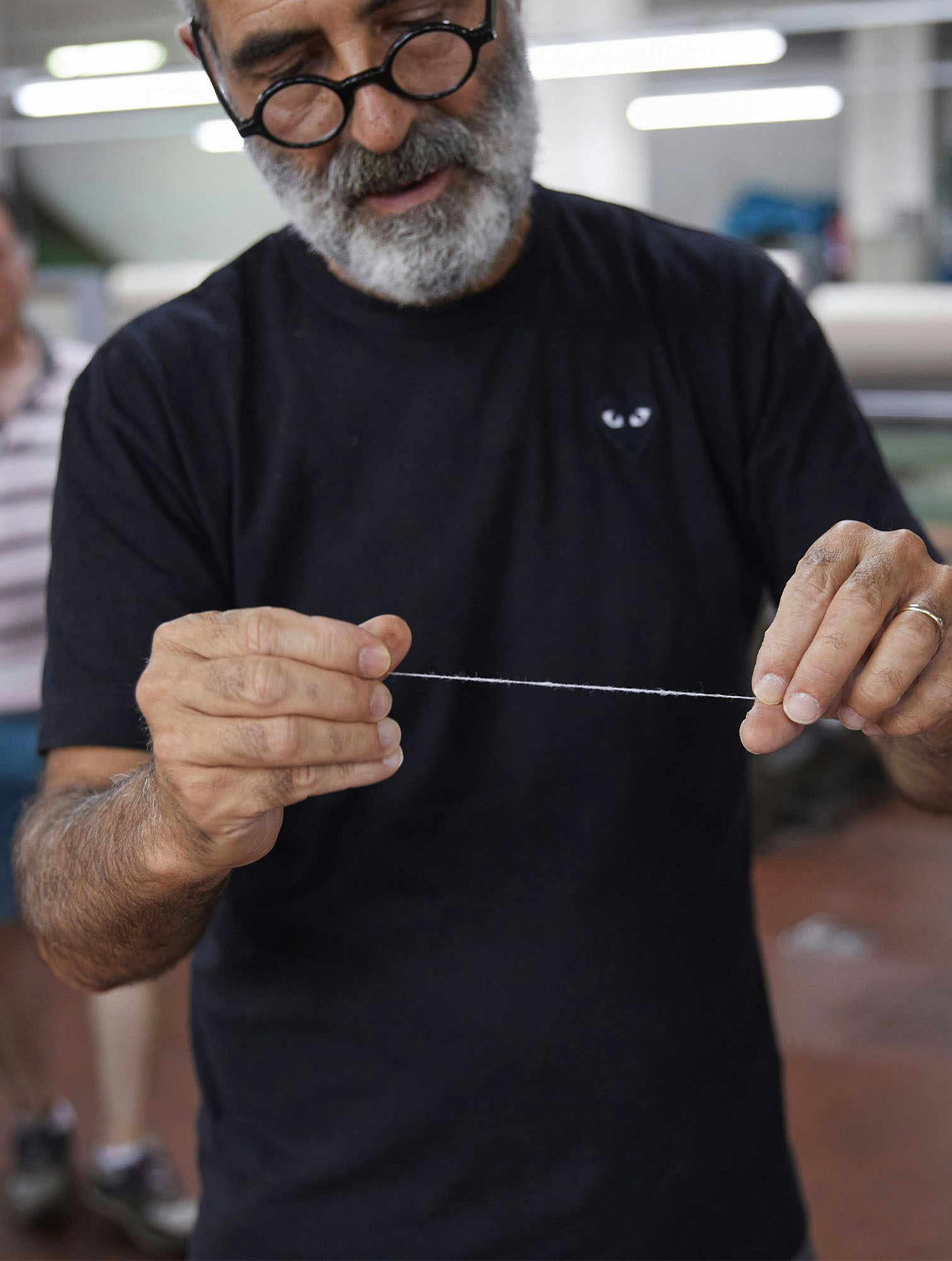

Their focused approach to sustainable denim makes Candiani a global jeans specialist. As a result of the sustainable jeans production, our Italian partner has also succeeded in developing a natural, biodegradable stretch material. That innovation took a full five years. But the time investment has paid off. To this day, there is no sustainable alternative to synthetic elastane. Without it, reports show that it takes hundreds of years to decompose stretch pants. Around 80% of most jeans today still contain elastane. Denim also ranks as one of the biggest polluters in the textile industry and beyond because of its massive water consumption. Meanwhile, Candiani was the first to develop a thread made of rubber that can be woven with sustainable cotton and is particularly durable.

Recycling instead of new production

Recycling is recognised as a central pillar of sustainable fashion production. To what extent does Candiani use the practice of recycling? In addition to reducing the use of water, natural chitosan is used to fix the typical blue indigo dye. Chitosan serves as a sustainable alternative to commonly used synthetic polyvinyl alcohol. This chemical fixes the dye, but eventually migrates into the water supply during washing, in the form of microplastics. Chitosan is commonly extracted from shrimp shells. But even here, the breeding farms do not live up to ecological and ethical standards. Candiani, however, discovered the innovative material in fungi. This alternative source is not only biodegradable, but also purifies the waste water. Overall, our Italian partner has succeeded in reducing water consumption in the factory by 75% and the use of chemicals by as much as 65%.

Candiani’s 3 core values

A powerful partnership

What initially appeared to be a major challenge, has made Candiani one of the most important leading denim suppliers today, with the highest standards in sustainability and innovation. It is also one of the reasons why windsor. relies on Candiani as one of its key partners in regard to environmental protection. The interest in environmentally friendly textiles and sustainable production processes is also steadily growing among windsor. customers. Because with each new generation comes a greater demand for quality and sustainability. This trend will continue to grow and strengthen in the future.